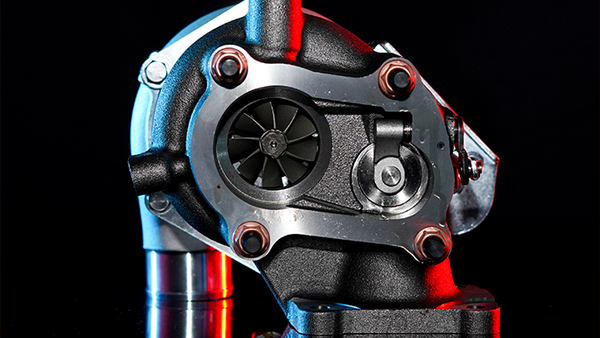

When it comes to managing heat in a turbocharged setup, two popular options stand out—turbo blankets and heat wraps. But which one is better for your build? Both serve to reduce under-hood temperatures, improve efficiency, and protect surrounding components. However, they have distinct differences in performance, durability, and application. This blog will compare turbo blankets vs. heat wraps to help you make the right choice.

What Is a Turbo Blanket?

A turbo blanket is a specialized thermal barrier designed to cover the turbine housing of a turbocharger. It helps contain heat within the turbo, reducing heat transfer to surrounding engine bay components.

Benefits of a Turbo Blanket:

✅ Reduces under-hood temperatures – Keeps engine bay components cooler.

✅ Improves turbo efficiency – Retains heat within the turbine for better exhaust gas velocity.

✅ Enhances spool time – Maintains optimal temperature for faster response.

✅ Protects surrounding components – Prevents excessive heat damage to hoses, wiring, and intake systems.

Best Applications for a Turbo Blanket:

-

Ideal for street performance and daily drivers looking to reduce heat soak.

-

Works well in tight engine bays where heat buildup is an issue.

-

Great for ceramic-coated or internally-gated turbos that require additional heat control.

What Is Heat Wrap?

Heat wrap is a high-temperature insulation material that is wrapped around exhaust components, including turbo manifolds, downpipes, and headers. It helps to retain heat within the exhaust system, improving overall thermal efficiency.

Benefits of Heat Wrap:

✅ Prevents heat loss – Retains heat in the exhaust system, increasing efficiency.

✅ Reduces surface temperatures – Lowers direct heat exposure to engine components.

✅ Increases exhaust gas velocity – Hotter gases move faster, improving turbo response.

✅ Budget-friendly solution – More affordable than turbo blankets and easy to install.

Best Applications for Heat Wrap:

-

Works best on exhaust manifolds, headers, and downpipes.

-

Ideal for track cars and race applications where extreme heat is generated.

-

Suitable for vehicles with larger turbos that don’t require direct turbo insulation.

Turbo Blanket vs. Heat Wrap: Which One Should You Choose?

| Feature | Turbo Blanket | Heat Wrap |

|---|---|---|

| Heat Reduction | High – Direct insulation for turbo | Moderate – Best for exhaust components |

| Turbo Efficiency | Improves spool time | Helps maintain exhaust velocity |

| Durability | Long-lasting, resistant to heat cycling | Can degrade over time, especially with moisture exposure |

| Installation | Simple – Fits over turbo | Requires wrapping around components |

| Best Use Case | Street, performance, daily driving | Track, race, high-performance builds |

| Cost | Higher upfront cost | Budget-friendly option |

Final Verdict: Which One Should You Use?

🔹 If you want to maximize turbo efficiency, reduce heat soak, and improve spool time, a turbo blanket is the best choice.

🔹 If you need a cost-effective way to reduce heat from exhaust manifolds, headers, or downpipes, heat wrap is a solid option.

🔹 For ultimate heat management, using both together can provide the best results.